Picture of empty shelves amidst the COVID-19 pandemic. Photo and visuals by Lauren Hough

LAUREN HOUGH | OPINION REPORTER | lhough@butler.edu

This article serves as a warning to all of you 20-something-year-old procrastinators — like myself — who can be found scouring Amazon two days before your holiday party for the perfect gift. Please, of all years, choose this one to be on top of your sh*t. You’ll thank me later.

This plea stems from a single, unavoidable reality we are facing — the supply chain crisis.

The phrase “supply chain” has suddenly overwhelmed the public eye and become the source of many sleepless nights for business officials. But for some, it’s nothing more than a buzzword that’s used to explain slow restaurant service and heightened grocery prices.

In order to recover from the crisis we face, it is vital that everyone understands this fundamental aspect of our society.

As college students, we will play a critical role in managing the future of global supply chains. Because of this, it’s especially important that our generation understands the factors and consequences of this crisis.

Dr. Jane Siegler, assistant professor of operations and supply chain management, recognizes the importance of our role as rising members of the workforce.

“I ask students ‘what is a supply chain?’ and everybody kind of has that blank face,” Siegler said.

Let’s fix that blank face, shall we?

Lesson number one: Supply Chains

Supply chains are essentially the interdependent channels that are required to turn raw materials into finished goods that are then distributed to consumers. While they are often described as linear processes, in reality, supply chains are deeply connected, misunderstood webs of manufacturers, distributors, wholesalers, retailers and much much more. I personally believe “chain” is the wrong word, as they are more of a network.

Siegler likes to describe supply chains as a puzzle.

“A supply chain is this intricate puzzle where every single piece needs to fit exactly — like the place and time — for everything to go smoothly,” Siegler said.

Supply Chain networks branch out from a single source — the company being analyzed.

Let’s visualize this puzzle.

A company has primary suppliers that are also referred to as “tier 1 suppliers,” who in turn, have their own suppliers — to the original company, these are “tier 2 suppliers” — who have their own suppliers, who have their own suppliers — and so on and so forth. Additionally, companies have customers who have their own customers, who have their own customers, who have their own customers — you get the idea.

As if this isn’t confusing enough, it gets trickier — and harder to trace — when suppliers and consumers interact with other suppliers and consumers. Don’t forget that each of these individual networks are also interconnected to other company and industry networks as a result of shared suppliers and distribution channels.

So why is this a big deal? Until recently, many supply chains weren’t traced due to their complicated nature. This inattention leads to disruptions when one intermediary within the network fails to deliver because it impacts everyone below it on the chain.

This is why the COVID-19 pandemic impacted global supply chains in a major way: intermediaries stopped delivering products. This brings us to some basic economics.

Lesson number two: Shortages

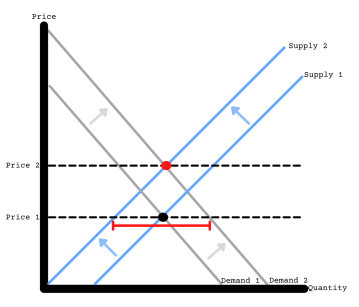

Shortage and price increases can be explained using a simple supply and demand diagram.

The graph represents what supply and demand looked like in the American economy before and after the COVID-19 pandemic. The intersection of supply 1 and demand 1 show the price level before lockdowns. Supply 2 and demand 2 represent what happened as a result of COVID-19 changes to the market.

The COVID-19 pandemic played a major role in triggering the supply chain crisis because it caused a labor shortage as workers were laid off and many never went back to work. This labor shortage is one major reason — amongst many others — that supply of available goods has decreased. Note the blue line shifting to the left on the pictured graph.

As a result of restrictions throughout the pandemic, consumer demand increased. Notice the rightward shift of the grey line.

Keep in mind, there are dozens of factors that play a role in these supply and demand shifts. Siegler points out company structures as one of these factors.

“Over the last 20 years, several manufacturing companies became very lean,” Siegler said. “So, there is no extra of anything: no extra time, no extra inventory, no extra resources.”

The opposing relationship between supply and demand movement over the course of the pandemic is what caused the product shortages and price increases we are now experiencing. The black dot on the graph is where prices used to lie; if companies continue to sell products at the same prices as before, major shortages occur — as shown by the red bracket — which is why shelves appear empty, products are put on backorder and shipping takes longer than normal. Essentially, more is being demanded than the market can supply.

Alternatively, companies can raise prices to where current supply and demand meet — depicted by the red dot — or find ways to cut costs elsewhere, like using lower-quality materials or lowering labor wages, which is yet another reason the workforce is slow to return.

Steven Protogere, junior entrepreneurship and innovation major, owns a watch company and has faced this very issue himself.

“Companies like mine have switched to other countries (for supply)…” Protogere said. “They might not be the same quality, but it gets the job done.”

So what does this mean for us?

The supply chain changes happening around us right now are monumental. It is our responsibility as the rising workforce to learn from past mistakes and avoid them in the future. We also need to come to terms with the fact that the labor shortage and supply chain disruptions will interfere with our lives as well. We can anticipate a rise in prices and plenty of backorders this holiday season.

Alex Brinkman, senior marketing and entrepreneurship and innovation major, works for BU Tees and has experienced supply chain-induced shortages firsthand. For those of you that do end up waiting until the last minute to buy holiday gifts, Brinkman has a suggestion.

“My biggest suggestion to college students is going to be shopping locally,” Brinkman said. “Local companies are usually pretty well stocked in terms of their products and they’re not going to overpromise.”

So order those holiday gifts now, shop locally if you can, share your stock of toilet paper, be patient with the single server at the drive-through window and remember that our world has been shaken by a natural disaster with an unforeseeable end.

Additional resources:

Defining the Supply Chain – Book with similar diagram and additional resources

Supply Chain Management for Kids – Applied and visual supply chain management resource